In the intricate web of industrial piping systems, the butt welding barrel nipple emerges as a linchpin, ensuring seamless fluid and gas transfer across diverse sectors. At Dingyang, we have dedicated ourselves to perfecting this crucial component, crafting butt welding barrel nipples that stand as a testament to our commitment to quality, innovation, and reliability.

Unveiling the Design Marvel

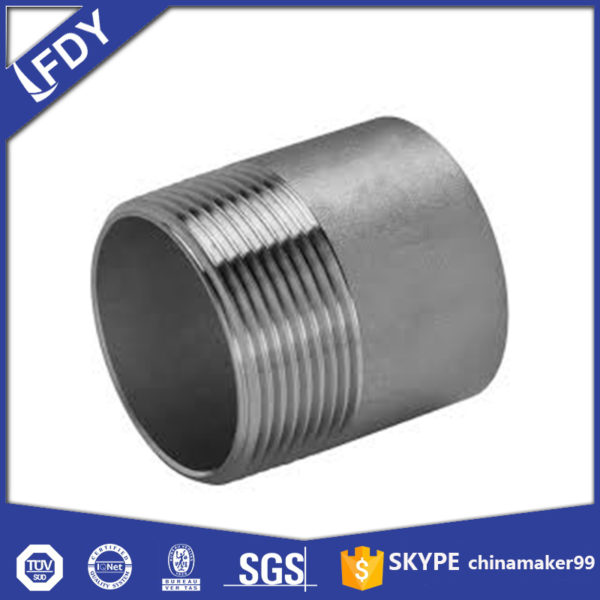

Dingyang‘s butt welding barrel nipple is engineered with a focus on functionality and durability. The sleek, cylindrical design allows for easy integration into various piping configurations. Its smooth internal bore minimizes fluid resistance, facilitating efficient flow and reducing energy consumption. The external surface is precisely machined, providing a flat and even welding surface that ensures a strong, leak – proof joint when mated with pipes.

One of the key design features is the precise wall thickness distribution. Through advanced engineering calculations and simulations, we have optimized the wall thickness to withstand high pressures and mechanical stresses without adding unnecessary weight. This not only enhances the performance of the nipple but also contributes to cost – effectiveness in material usage. Additionally, the beveled ends of the nipple are designed to promote proper fusion during the welding process, creating a joint that is as strong as the parent materials.

Material Mastery

The choice of materials is of utmost importance in the production of butt welding barrel nipples, and Dingyang spares no effort in sourcing the highest – quality materials. We offer a wide range of options, including carbon steel, stainless steel, alloy steel, and duplex stainless steel, each selected to meet the specific requirements of different applications.

For applications in general industrial settings where cost – effectiveness and moderate corrosion resistance are needed, our carbon steel nipples are an excellent choice. They are manufactured from high – grade carbon steel alloys that provide good strength and durability. In more corrosive environments, such as those found in chemical processing plants or marine installations, our stainless steel nipples shine. The chromium and nickel content in stainless steel alloys offers superior corrosion resistance, protecting the nipples from degradation and ensuring a long service life. Alloy steel nipples, on the other hand, are designed for high – temperature and high – pressure applications, such as in power generation plants, where they can withstand extreme conditions while maintaining their structural integrity.

Precision Manufacturing

At Dingyang, we employ state – of – the – art manufacturing processes to produce our butt welding barrel nipples. The production begins with the careful selection of raw materials, which are then subjected to strict quality checks.

After machining, the nipples are heat – treated to improve their mechanical properties. Heat treatment processes, such as annealing, normalizing, and quenching and tempering, are carefully controlled to achieve the desired strength, hardness, and toughness. This not only enhances the performance of the nipples but also improves their resistance to wear and fatigue. Finally, the nipples are subjected to rigorous quality inspections, including dimensional checks, non – destructive testing (such as ultrasonic testing and magnetic particle inspection), and hydrostatic pressure testing, to ensure that they meet our stringent quality requirements.

In the power generation sector, butt welding barrel nipples are used in steam pipelines, cooling water systems, and fuel supply lines. Their high – temperature and high – pressure resistance properties make them ideal for withstanding the extreme conditions found in power plants. They also play a crucial role in the construction industry, where they are used in plumbing systems, heating and ventilation systems, and fire protection systems. Their ease of installation and reliable performance make them a preferred choice for contractors and engineers.

In conclusion, Dingyang‘s butt welding barrel nipples are a cut above the rest. With their innovative design, high – quality materials, precision manufacturing, and wide range of applications, they offer a solution that meets the most demanding requirements of modern industries. When it comes to reliable and efficient piping connections, Dingyang’s butt welding barrel nipples are the name you can trust.

Language

Language Espanol

Espanol English

English Italian

Italian عربى

عربى

Skype: chinamaker99

Skype: chinamaker99  Tel: 86-316-5120812

Tel: 86-316-5120812  Email:

Email:  Whatsapp:

Whatsapp: