Nipple (pipe joint) is a structurally simple and functionally critical connecting component in industrial pipeline systems, mainly used to achieve rapid docking and sealing between two sections of pipelines, pipelines and valves or equipment interfaces. It plays an irreplaceable role in pipeline systems in multiple industries such as petroleum, chemical, power, municipal, and mechanical manufacturing. Compared with other complex pipeline connectors, Nipple has a compact structure, easy installation, and strong adaptability. It can meet the connection needs of different specifications of pipelines while ensuring the sealing and stability of pipeline systems. It is one of the basic connectors with large usage and wide application range in industrial production. As the “connecting link” of the pipeline system, the quality and performance of Nipple directly affect the operational safety of the entire pipeline system. Its design rationality, material adaptability, and processing accuracy are closely related to the transportation efficiency of the pipeline medium and the service life of the system. Therefore, a deep understanding of Nipple’s relevant characteristics and application points is of great significance for the construction and maintenance of industrial pipeline systems.

From the perspective of structural form and function, pipe joints can be mainly divided into several basic types. The most common type is a straight pipe joint with consistent thread specifications at both ends, used to directly connect two internally threaded ports of the same specification. When connecting ports of different specifications, a reducer joint is used, with threads of different sizes machined on both ends. One end of the closed pipe joint is an external thread, and the other end is a sealed solid end, used to close the pipe port. There is also a special type of pipe joint, whose outer middle part is processed into a hexagonal shape, making it easy to install and disassemble with a wrench, improving the convenience of construction and maintenance. These different types of pipe joints, through precise thread matching, form flexible and reliable connection nodes in the pipeline system.

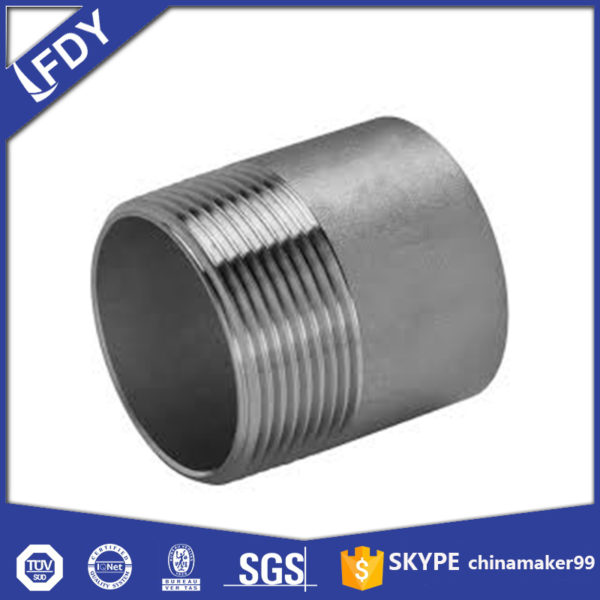

The core value of Nipple lies in its efficient connection and sealing function, which cannot be achieved without its reasonable structural design and suitable material selection. From a structural perspective, Nipples are typically cylindrical pipe fittings that can be machined into threaded, welded, or socket forms at both ends according to connection requirements. Among them, threaded Nipples are the most widely used, and their threads at both ends can accurately fit the interfaces of pipelines, valves, and other components. By tightening, a sealed connection can be achieved without the need for complex welding processes, greatly improving installation efficiency and facilitating subsequent maintenance and disassembly. The welded Nipple is fixedly connected to the pipeline through welding, with high connection strength and good sealing performance. It is suitable for high pressure, high temperature or high vibration working conditions and can effectively avoid medium leakage. The socket type Nipple is mainly used for connecting smaller diameter pipelines, with a simple structure and low cost, which can quickly achieve pipeline connection and meet the needs of low-pressure working conditions.

The application fields of pipe joints are extremely wide, covering almost all industries related to pipeline transportation. In the building water supply and drainage system, various types of pipe joints are used to connect water pipes and fire pipes. In industrial production, the connection function of pipe joints is indispensable from the pipelines of petrochemical equipment to the hydraulic and pneumatic circuits of mechanical equipment. In heating and air conditioning systems, they ensure the smooth flow of heat or refrigerant in complex pipelines. Even in precision settings such as laboratories and medical devices, miniaturized pipe joints play an indispensable role. Its core value lies in providing a standardized and modular connection solution, making the installation, modification, and maintenance of pipeline systems more flexible and efficient.

With the continuous development of industrial technology, the requirements for connecting components in pipeline systems are also constantly increasing, and Nipple’s production process and performance are also continuously optimized and upgraded. At present, the industry is further improving the corrosion resistance, high temperature resistance, and sealing performance of Nipple by improving manufacturing processes, optimizing material ratios, and enhancing processing accuracy, so that it can adapt to more stringent working conditions. As an indispensable core connector in industrial pipeline systems, the quality and performance of Nipple are directly related to the safety and efficiency of industrial production. Therefore, strengthening research and production control of Nipple, continuously improving its quality, has important practical significance and industrial value.

Language

Language Espanol

Espanol English

English Italian

Italian عربى

عربى

Skype: chinamaker99

Skype: chinamaker99  Tel: 86-316-5120812

Tel: 86-316-5120812  Email:

Email:  Whatsapp:

Whatsapp: