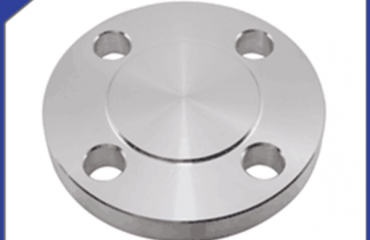

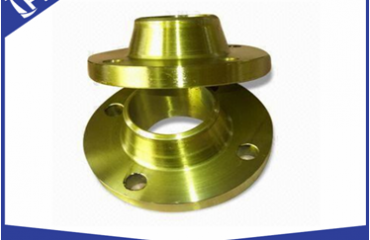

Alloy steel flanges stand as vital links in industrial piping systems, bridging pipes, valves, and equipment while enduring tough operational conditions. Unlike standard steel flanges, their alloy composition—blending elements like chromium, nickel, and molybdenum—gives them unique advantages that make them indispensable across multiple sectors.

One of the most notable strengths of alloy steel flanges is their resistance to harsh environments. In settings with high humidity, chemical exposure, or saltwater (such as coastal refineries or marine facilities), these flanges resist rust and corrosion far better than carbon steel alternatives. This resistance stems from the alloying elements: chromium forms a protective oxide layer on the surface, while molybdenum enhances durability against acidic or alkaline fluids. For industries like petrochemicals, where pipes carry corrosive solvents, this trait prevents leaks and extends the system’s lifespan.

Temperature adaptability is another key feature. Alloy steel flanges maintain their structural integrity in extreme heat and cold. In power plants, for example, they connect pipes in boilers that reach temperatures over 500°C, without warping or losing strength. Similarly, in cryogenic applications—like LNG storage—they remain stable at sub-zero temperatures, ensuring no cracks or failures in the piping network. This versatility eliminates the need for frequent replacements, cutting down on maintenance costs for businesses.

When selecting alloy steel flanges, several factors demand attention. First, pressure rating must match the system’s requirements. Flanges used in high-pressure oil pipelines, for instance, need a higher pressure class than those in low-pressure water distribution systems. Second, the alloy grade matters: grades like A182 F5 (containing chromium and molybdenum) suit high-temperature uses, while F304 (with nickel) excels in corrosive environments. Third, size and dimensions must align with the pipes to ensure a tight, leak-free fit—even small mismatches can lead to operational risks.

Proper maintenance further maximizes the value of alloy steel flanges. Regular inspections, such as visual checks for surface damage or ultrasonic testing to detect internal flaws, help catch issues early. Cleaning the flanges with non-abrasive solutions removes dirt and chemical residues that could erode the surface over time. Additionally, ensuring proper bolt torque during installation prevents uneven pressure, which can cause flange deformation.

In summary, alloy steel flanges offer a combination of corrosion resistance, temperature stability, and strength that meets the demands of modern industry. From oil rigs to pharmaceutical plants, their ability to perform reliably in diverse conditions makes them a top choice for engineers and facility managers. By understanding their key traits and following best practices for selection and maintenance, industries can ensure safe, efficient, and long-lasting piping operations.

Language

Language Espanol

Espanol English

English Italian

Italian عربى

عربى

Skype: chinamaker99

Skype: chinamaker99  Tel: 86-316-5120812

Tel: 86-316-5120812  Email:

Email:  Whatsapp:

Whatsapp: