Butt welded fittings stand as foundational elements in modern piping systems, enabling robust, permanent connections that prioritize reliability and performance. Unlike mechanical fittings that rely on threads or fasteners, these components form a seamless bond through welding, merging the fitting and pipe into a single structural unit. This design choice delivers unique advantages that make them a staple across industries requiring durable, leak-resistant piping solutions.

The defining strength of butt welded fittings lies in their homogeneous joint structure. During installation, the beveled ends of the fitting and pipe are aligned, and a full-penetration weld fills the gap, creating a connection with mechanical properties matching the base material. This eliminates weak points common in threaded or socketed fittings, such as loosening from vibration or crevice corrosion. The result is a joint capable of withstanding extreme pressure, temperature fluctuations, and mechanical stress—critical for systems operating at high temperatures (up to 1,000°F or higher) or pressures exceeding 1,000 psi.

Material versatility further enhances their utility. Butt welded fittings are manufactured from a wide range of materials to suit specific application needs: carbon steel for general industrial use, stainless steel (304, 316 grades) for corrosion resistance in chemical or food processing, alloy steel (Chrome-Moly) for high-temperature power generation, and duplex steel for offshore or marine environments. This adaptability ensures compatibility with diverse piping materials, allowing engineers to maintain consistency in system performance while addressing environmental or operational challenges.

Industrial applications for butt welded fittings span across sectors where reliability is non-negotiable. In the oil and gas industry, they are used in transmission pipelines, refineries, and offshore platforms, handling crude oil, natural gas, and corrosive hydrocarbons. The power generation sector relies on them for boiler systems, steam turbines, and heat recovery units, where resistance to high pressure and temperature is essential. They are also integral to the chemical processing industry, facilitating the safe transport of acids, solvents, and reactive chemicals without leakage risks. Additionally, they find use in marine engineering, aerospace, and municipal water treatment systems, where long-term durability reduces maintenance costs and downtime.

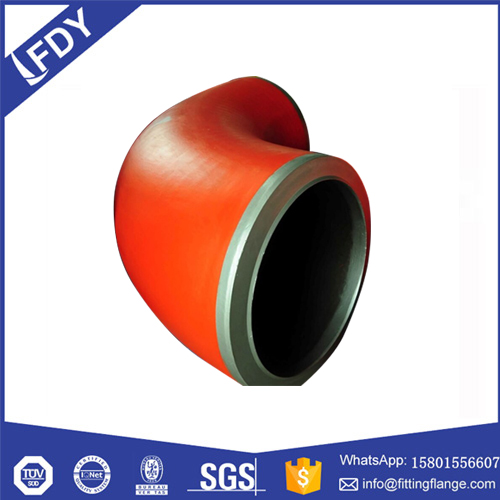

Common types of butt welded fittings are engineered to address specific piping needs: elbows (45°, 90°, 180°) for changing flow direction, tees for branching pipelines, reducers (concentric or eccentric) for connecting different pipe diameters, caps for sealing pipe ends, and crosses for four-way flow distribution. Each type adheres to international standards such as ASME B16.9, DIN 2605, or EN 10253, ensuring dimensional consistency and interchangeability across global markets.

Selecting the right butt welded fitting requires careful consideration of key factors. Material compatibility with the existing piping system prevents galvanic corrosion and ensures uniform strength. Pressure and temperature ratings must align with operational conditions to avoid joint failure. Dimensional accuracy (pipe size, wall thickness) guarantees proper fit and weld quality, while compliance with industry standards confirms adherence to safety and performance benchmarks. Installation by certified welders, using proper beveling, alignment, and welding techniques, further optimizes joint integrity.

Language

Language Espanol

Espanol English

English Italian

Italian عربى

عربى

Skype: chinamaker99

Skype: chinamaker99  Tel: 86-316-5120812

Tel: 86-316-5120812  Email:

Email:  Whatsapp:

Whatsapp: