Carbon steel flanges are vital connectors in piping systems, linking pipes, valves, pumps, and other equipment to form a secure, detachable joint. Their widespread adoption stems from a blend of practical advantages that align with the needs of diverse industrial sectors. This article explores key aspects of carbon steel flanges, including their core benefits, common applications, selection criteria, and maintenance practices to support optimal performance.

A standout feature of carbon steel flanges is their exceptional mechanical strength. Crafted from carbon steel, they boast high tensile and compressive strength, enabling them to withstand moderate to high pressure and temperature ranges typical of industrial operations. Unlike more expensive alloy alternatives, carbon steel flanges offer cost-effectiveness, making them a preferred choice for large-scale projects where budget efficiency is a priority. Additionally, they exhibit good weldability, allowing for straightforward installation and integration with existing piping systems, which reduces downtime during setup or repairs.

The versatility of carbon steel flanges is evident in their wide array of applications. They are a staple in the oil and gas industry, used in pipelines for crude oil extraction, natural gas transportation, and refining processes. In the chemical industry, they connect pipes carrying non-highly corrosive chemicals, solvents, and intermediates. Power generation plants, both thermal and nuclear, rely on them for steam and water circulation systems. They also find use in water treatment facilities, HVAC systems, and general manufacturing, where reliable pipe connections are essential for smooth operations.

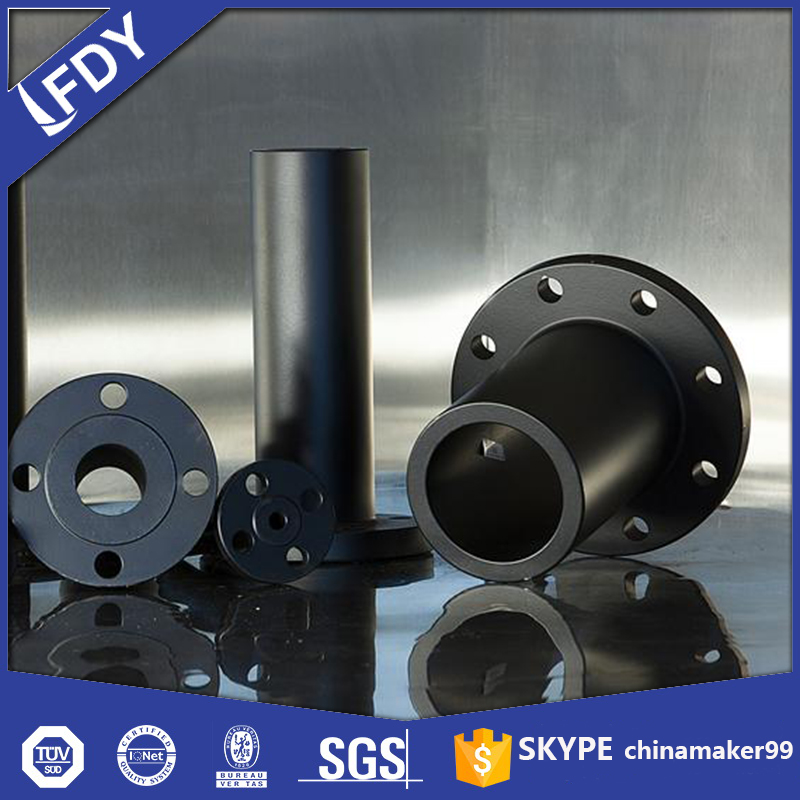

Selecting the right carbon steel flange requires careful consideration of several factors. First, operating conditions such as pressure and temperature must be matched to the flange’s rating—standard ratings include Class 150, 300, and 600, which dictate the maximum pressure the flange can handle. Second, connection standards (e.g., ANSI, DIN, JIS) must align with the existing piping components to ensure compatibility. Flange type is another key factor: weld neck flanges are ideal for high-pressure applications, slip-on flanges for low-pressure scenarios, and blind flanges for sealing pipe ends. Additionally, environmental factors should be assessed—if exposed to moisture or mild corrosion, surface treatments like galvanization or painting can extend service life.

Proper maintenance is crucial to prolong the lifespan of carbon steel flanges. Regular inspections should check for signs of corrosion, leakage, or deformation, especially in harsh environments. Sealing surfaces must be kept clean and free of damage, as scratches or debris can compromise the joint’s integrity and lead to leaks. When disassembling flanges, avoid excessive force that could warp the structure. If corrosion is detected, prompt cleaning and reapplication of protective coatings can prevent further deterioration.

While carbon steel flanges have limitations—such as susceptibility to corrosion in highly acidic or salty environments—their advantages often outweigh these drawbacks for many applications. By selecting the appropriate type, adhering to installation guidelines, and implementing regular maintenance, users can ensure the reliability and longevity of carbon steel flange connections. As industrial infrastructure continues to expand and evolve, the demand for these versatile, cost-effective components remains consistent, solidifying their place in global piping systems.

Language

Language Espanol

Espanol English

English Italian

Italian عربى

عربى

Skype: chinamaker99

Skype: chinamaker99  Tel: 86-316-5120812

Tel: 86-316-5120812  Email:

Email:  Whatsapp:

Whatsapp: