Flange standards are critical for industrial connections, but their value lies in understanding the key parameters that define performance and compatibility. These parameters, outlined in global standards like ASME B16.5, EN 1092-1, and ISO 7005-1, act as a common language for engineers, procurement teams, and manufacturers, ensuring flanges work seamlessly in diverse systems—from oil pipelines to chemical reactors.

Pressure-Temperature (PT) Ratings: The Foundation of Safety

Pressure-temperature ratings are the most non-negotiable parameter in flange standards, as they determine a flange’s ability to withstand operational stress. Every standard assigns PT ratings based on the flange’s material and design. For example, ASME B16.5 specifies that a Class 300 carbon steel flange (A105) can handle up to 740 psi at 100°F, but this drops to 420 psi when exposed to 600°F. EN 1092-1 uses PN (Pressure Nominal) ratings: a PN 25 stainless steel flange (X5CrNi18-10) typically resists 25 bar (363 psi) at 20°C, but its capacity decreases to 11 bar (159 psi) at 400°C. Ignoring PT ratings risks leaks, flange deformation, or even system failure—especially in high-temperature, high-pressure industries like power generation.

Dimensional Accuracy: Ensuring Interchangeability

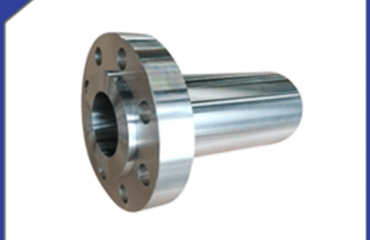

Flange standards leave no room for dimensional ambiguity, as even small discrepancies can prevent proper assembly. Key dimensional parameters include nominal size (e.g., 4 inches in ASME, DN 100 in EN), bolt hole count and spacing, flange thickness, and face type. For instance, an ASME Class 150 6-inch weld neck flange has 12 bolt holes spaced 3.875 inches apart, while an EN PN 16 DN 150 slip-on flange has 8 bolt holes with a 210 mm pitch circle diameter. The face type—such as raised face (RF), flat face (FF), or ring type joint (RTJ)—is also standardized: RF flanges (common in most industries) use a raised sealing surface to enhance gasket contact, while RTJ flanges (used in high-pressure oil and gas) rely on a metal-to-metal seal. Dimensional compliance ensures flanges from different manufacturers can be swapped, simplifying maintenance and reducing downtime.

Material Specifications: Matching Flanges to Environments

Flange standards strictly define acceptable materials, linking each material to specific performance attributes. Carbon steel (e.g., ASME A105, EN S235JR) is widely used for low-cost, low-corrosion applications like water pipelines, as it offers good strength at moderate temperatures. Stainless steel (e.g., ASME A182 F304, EN X5CrNi18-10) is preferred for chemical plants or food processing facilities, where resistance to rust and acidic fluids is critical. Alloy steels (e.g., ASME A182 F91) are chosen for high-temperature systems like boiler tubes, as they retain strength at temperatures above 1000°F. Standards also outline material testing requirements—such as tensile strength and impact resistance tests—to ensure consistency. Using a material not approved by the relevant standard can lead to premature corrosion or structural failure, especially in harsh environments.

Gasket Compatibility: Preventing Leaks

Gaskets are the unsung heroes of flange connections, and flange standards directly tie gasket type to flange design. For example, ASME B16.5 recommends spiral wound gaskets for Class 300-2500 flanges (high pressure), while non-asbestos sheet gaskets work for Class 150 flanges (low pressure). EN 1092-1 specifies that PN 6-PN 16 flanges often use elastomeric gaskets, while PN 40+ flanges require more robust options like metal-jacketed gaskets. The flange face type also dictates gasket choice: FF flanges need flat gaskets to avoid damage, while RF flanges pair with gaskets that match the raised surface. Mismatched gaskets and flanges are a top cause of leaks, making this parameter essential for operational integrity.

Language

Language Espanol

Espanol English

English Italian

Italian عربى

عربى

Skype: chinamaker99

Skype: chinamaker99  Tel: 86-316-5120812

Tel: 86-316-5120812  Email:

Email:  Whatsapp:

Whatsapp: