Introduction

In industrial piping systems, flanges play a crucial role in connecting pipes, valves, pumps, and other equipment securely. Among the various types of flanges available, forged flanges stand out for their superior strength, durability, and reliability. At DingYang, we specialize in manufacturing high-quality forged flanges that meet stringent industry standards, ensuring optimal performance in demanding applications.

What is a Forged Flange

A forged flange is a type of pipe flange produced through the forging process, which involves shaping metal under high pressure and temperature. Unlike cast flanges, forged flanges have a denser grain structure, making them stronger and more resistant to impact, pressure, and extreme temperatures.

Key Advantages of Forged Flanges

High Strength & Durability – The forging process enhances the mechanical properties of the metal, ensuring excellent load-bearing capacity and resistance to wear.

Superior Leak Prevention – Tight grain structure minimizes porosity, reducing the risk of leaks in high-pressure systems.

Wide Temperature & Pressure Tolerance – Suitable for extreme conditions in oil & gas, petrochemical, and power generation industries.

Long Service Life – Resistant to corrosion and fatigue, reducing maintenance costs over time.

Types of Forged Flanges Offered by DingYang

At DingYang, we produce a wide range of forged flanges to meet diverse industrial needs

1. Weld Neck Flanges (WN)

Designed for high-pressure applications.

Features a tapered hub for smooth stress distribution.

Ideal for critical pipelines in oil refineries and chemical plants.

2. Slip-On Flanges (SO)

Easy to install and align.

Suitable for low-pressure systems.

Commonly used in water treatment and HVAC systems.

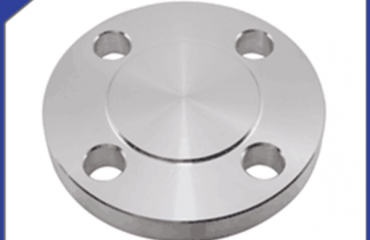

3. Blind Flanges (BL)

Used to seal the end of piping systems.

Essential for pressure testing and maintenance shutdowns.

4. Socket Weld Flanges (SW)

Provides high leakage integrity.

Best for small-diameter, high-pressure pipelines.

5. Threaded Flanges (TH)

No welding required; ideal for explosive environments.

Used in fuel gas and hydraulic systems.

Materials Used in DingYang Forged Flanges

We manufacture flanges from premium materials to ensure maximum performance

Carbon Steel (ASTM A105) – High strength for general applications.

Stainless Steel (ASTM A182 F304F316) – Excellent corrosion resistance.

Alloy Steel (ASTM A182 F11F22) – Suitable for high-temperature and high-pressure conditions.

Duplex & Super Duplex Steel – Superior resistance to pitting and cracking in harsh environments.

Applications of DingYang Forged Flanges

Our flanges are widely used in

Oil & Gas – Pipeline connections, refineries, and offshore platforms.

Chemical Processing – Acid and alkali-resistant systems.

Power Plants – High-pressure steam and cooling systems.

Water Treatment – Pumping stations and desalination plants.

Shipbuilding – Marine-grade corrosion-resistant flanges.

Conclusion

Forged flanges are essential components in industrial piping systems, offering unmatched reliability and performance. DingYang is committed to delivering top-quality forged flanges that meet global standards, ensuring safety and efficiency in every application. Whether you need standard or customized flanges, our expert team is ready to provide the best solutions for your project.

Contact DingYang today to discuss your forged flange requirements and experience excellence in engineering!

Language

Language Espanol

Espanol English

English Italian

Italian عربى

عربى

Skype: chinamaker99

Skype: chinamaker99  Tel: 86-316-5120812

Tel: 86-316-5120812  Email:

Email:  Whatsapp:

Whatsapp: