Butt welded fittings are commonly used in various industries such as oil and gas, petrochemical, and plumbing for connecting pipes. Proper installation of butt welded fittings is crucial to ensure a leak-proof and safe joint. Here are some steps to ensure the proper installation of butt welded fittings:

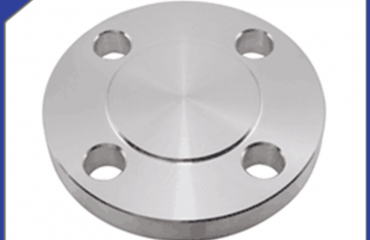

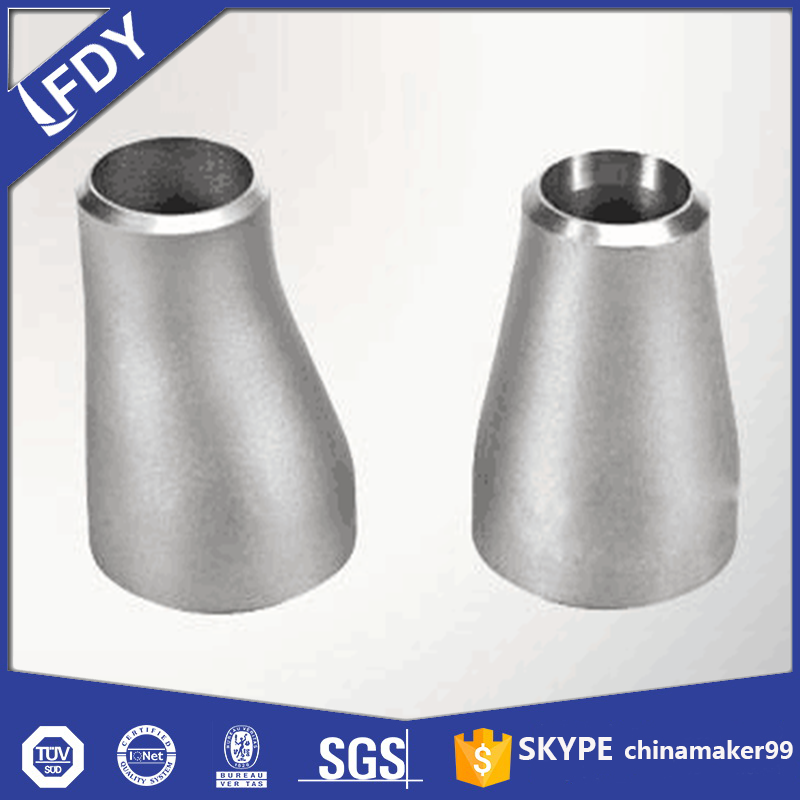

Select the right fitting: Before beginning the installation process, make sure you have selected the correct size, type, and material of the fitting. It is essential to match the fitting to the pipe specifications to ensure a tight and secure connection.

Prepare the pipes: Before welding the fittings, ensure that the ends of the pipes are properly cleaned and beveled. This will help in creating a smooth and even surface for the fitting to be welded onto.

Fit the fittings: Align the fitting with the pipe ends and make sure they are properly aligned. The fitting should fit snugly onto the pipe without any gaps or misalignment.

Welding process: Begin the welding process by using the appropriate welding technique, such as TIG welding, MIG welding, or stick welding, depending on the material of the fitting and the pipe. Ensure that the welding process is done by a qualified and experienced welder to avoid any defects or weak joints.

Cleaning and finishing: After the welding process is completed and the weld joint has been inspected, clean the weld area to remove any slag, spatter, or debris. Properly finish the weld joint to ensure a smooth and uniform surface.

Language

Language Espanol

Espanol English

English Italian

Italian عربى

عربى

Skype: chinamaker99

Skype: chinamaker99  Tel: 86-316-5120812

Tel: 86-316-5120812  Email:

Email:  Whatsapp:

Whatsapp: