Stainless steel flanges are integral components in industrial piping systems, providing secure connections for pipes, valves, pumps, and other equipment. Their durability, corrosion resistance, and versatility make them indispensable across sectors like oil and gas, chemical processing, and water treatment. This guide explores their types, materials, applications, and maintenance to help you make informed decisions for your projects.

Understanding Stainless Steel Flanges

Stainless steel flanges are circular discs with bolt holes, designed to join pipes or equipment while maintaining pressure and sealing integrity. Their composition—primarily chromium and nickel—gives them exceptional resistance to rust and chemical damage. Key advantages include:

Corrosion Resistance: Ideal for harsh environments, such as marine or chemical settings.

High Strength: Withstands extreme pressures (up to 2500 psi) and temperatures .

Low Maintenance: Minimal upkeep due to self-healing oxide layers.

Types of Stainless Steel Flanges

Flanges come in various designs tailored to specific applications:

Weld Neck Flanges: Feature a tapered hub for high-pressure systems, offering superior strength and reduced turbulence.

Slip-On Flanges: Slide over pipes and weld on both sides, suitable for low-to-medium pressure and easy installation.

Socket Weld Flanges: Used for small-diameter pipes, ensuring leak-proof connections in high-pressure scenarios.

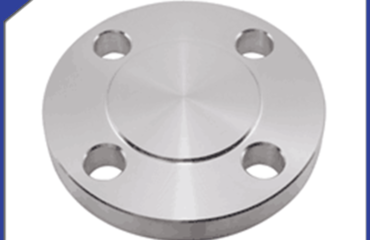

Blind Flanges: Solid discs that seal pipe ends, commonly used for maintenance or testing.

Lap Joint Flanges: Allow rotational alignment, ideal for frequent disassembly in low-pressure systems.

Threaded Flanges: Avoid welding in explosive environments, suitable for low-pressure applications.

Materials and Grades

Stainless steel grades vary in composition and performance:

304/304L: Cost-effective, widely used in general applications (e.g., food processing) .

316/316L: Contains molybdenum for enhanced resistance to chloride corrosion, ideal for marine and pharmaceutical industries.

Duplex Stainless Steel: Combines austenitic and ferritic structures for high strength and corrosion resistance in offshore and chemical plants.

Super Duplex: Exceptional resistance to pitting and crevice corrosion, used in subsea pipelines.

Always align material selection with environmental factors, such as chloride exposure or temperature extremes.

Applications Across Industries

Stainless steel flanges are pivotal in diverse sectors:

Oil and Gas: High-pressure pipelines, offshore platforms, and refineries.

Chemical Processing: Handling corrosive fluids in reactors and storage tanks.

Water Treatment: Chlorinated environments and wastewater systems.

Pharmaceutical and Food: Hygienic-grade flanges ensure contamination-free production.

Marine: Resist saltwater corrosion in shipbuilding and desalination plants.

Installation and Maintenance Best Practices

Installation Tips

Surface Preparation: Clean flanges thoroughly to remove oils, rust, or debris.

Gasket Selection: Use non-asbestos or rubber gaskets compatible with the fluid and pressure.

Welding Control: Maintain precise current to prevent overheating and material degradation .

Torque Uniformity: Tighten bolts diagonally to ensure even pressure distribution.

Maintenance Strategies

Regular Inspections: Check for leaks, corrosion, or loose bolts. Address issues promptly to avoid system failure.

Cleaning: Use mild detergents or solvents to remove contaminants; avoid abrasive tools.

Lubrication: Apply anti-seize compounds on threads to facilitate disassembly .

Corrosion Prevention: In chloride-rich environments, opt for 316L or duplex stainless steel and apply protective coatings.

Common Pitfalls to Avoid

Improper Material Selection: Using 304 in saltwater environments can lead to pitting .

Inadequate Welding: Poor weld quality weakens connections, increasing leak risks .

Neglecting Torque Specifications: Over-tightening causes flange deformation; under-tightening leads to leaks.

Standards and Compliance

Flanges must adhere to international standards like ASME B16.5 (pressure ratings, dimensions) and ASTM A182 (material properties) . These ensure compatibility and safety across global industries.

Future Trends

Sustainability: Growing use of recycled stainless steel (40% in 2024) and eco-friendly manufacturing processes.

Advanced Materials: Rising demand for duplex and super duplex flanges in high-stress applications.

Automation: CNC machining and automated forging improve precision and production efficiency.

Dingyang is a leading provider of high-quality stainless steel flanges, committed to delivering innovative solutions for diverse industrial needs. Contact us to explore tailored options for your projects.

Language

Language Espanol

Espanol English

English Italian

Italian عربى

عربى

Skype: chinamaker99

Skype: chinamaker99  Tel: 86-316-5120812

Tel: 86-316-5120812  Email:

Email:  Whatsapp:

Whatsapp: