Long barrel nipples, a specialized type of pipe fitting, play a pivotal role in the assembly and functionality of piping systems across a multitude of industries. Despite their often – overlooked status, these fittings are essential for creating secure, durable, and efficient connections that ensure the smooth flow of fluids.

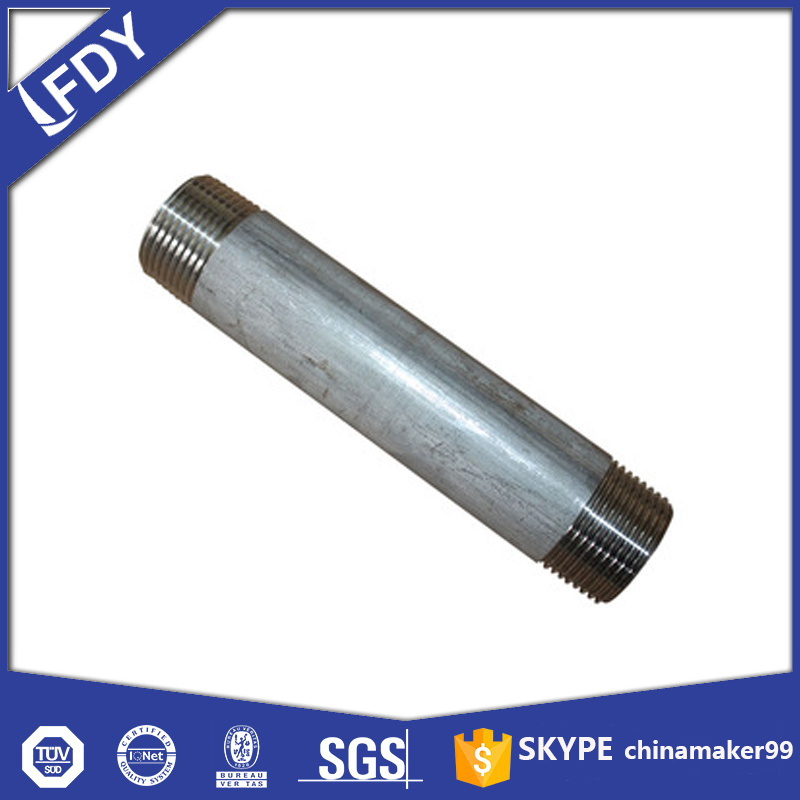

At their core, long barrel nipples are cylindrical pieces of pipe with threaded ends designed to connect other pipe components, such as valves, faucets, or additional lengths of pipe. Their elongated shape sets them apart from standard nipples, offering several distinct advantages. The extended length provides greater flexibility in installation, allowing for adjustments in pipe alignment and spacing. This is particularly beneficial in complex piping layouts where precise positioning is crucial.

One of the primary applications of long barrel nipples is in plumbing systems. In residential and commercial buildings, they are used to connect water supply lines, drainage systems, and gas pipes. For instance, when installing a new sink or faucet, long barrel nipples can bridge the gap between the existing pipes and the fixture, ensuring a watertight and secure connection. Their threaded ends enable easy attachment and detachment, facilitating maintenance and repairs without the need for extensive disassembly of the entire piping network.

In industrial settings, long barrel nipples are equally indispensable. In manufacturing plants, refineries, and chemical processing facilities, these fittings are employed to create robust piping systems that can withstand high pressures, extreme temperatures, and corrosive substances. The extended length of the nipple allows for the incorporation of additional components, such as gauges, filters, or sensors, along the pipeline. This not only enhances the functionality of the system but also enables better monitoring and control of the fluid flow.

The material composition of long barrel nipples is another critical factor in their performance. Commonly made from materials such as steel, brass, and plastic, each type offers specific properties suited to different applications. Steel nipples, for example, are known for their strength and durability, making them ideal for high – pressure industrial applications. Brass nipples, on the other hand, provide excellent corrosion resistance, making them a popular choice for plumbing and marine applications. Plastic nipples are lightweight, cost – effective, and resistant to chemical corrosion, making them suitable for applications involving non – potable water or chemical fluids.

However, the use of long barrel nipples also presents some challenges. Over time, the threaded connections may loosen due to vibrations or thermal expansion and contraction, leading to leaks. Regular inspection and maintenance are necessary to ensure the integrity of the connections. Additionally, improper installation or the use of low – quality nipples can compromise the performance of the entire piping system, potentially resulting in costly repairs and downtime.

In conclusion, long barrel nipples are a vital component in piping systems, offering versatility, durability, and functionality. Their role in plumbing and industrial applications cannot be overstated, as they enable the creation of reliable connections that are essential for the efficient transfer of fluids. While they come with their own set of challenges, proper installation, material selection, and maintenance can maximize their performance and lifespan. As industries continue to evolve and demand more efficient and reliable piping solutions, the importance of long barrel nipples will only increase, solidifying their status as a key element in modern piping infrastructure.

Language

Language Espanol

Espanol English

English Italian

Italian عربى

عربى

Skype: chinamaker99

Skype: chinamaker99  Tel: 86-316-5120812

Tel: 86-316-5120812  Email:

Email:  Whatsapp:

Whatsapp: