Threaded fittings are the unsung heroes of modern piping systems, enabling secure, adaptable connections across industries. Their threaded design allows for easy assembly, disassembly, and maintenance, making them a cornerstone in applications ranging from residential plumbing to high-pressure industrial pipelines. This guide explores the key types, materials, installation techniques, and industry uses of threaded fittings, helping you navigate their diverse applications with confidence.

What Are Threaded Fittings?

Threaded fittings are mechanical connectors featuring helical threads that create a tight, reusable seal when joined with compatible pipes or components. Unlike welded or flanged connections, they rely on rotational force to secure joints, offering:

Flexibility: Easily adjusted or replaced without specialized tools.

Cost Efficiency: Lower installation and repair costs due to simplified assembly.

Leak Resistance: Properly applied sealants ensure reliability in pressures up to 3,000 PSI and temperatures from -20°F to 1,500°F.

Standardization: Global thread profiles ensure compatibility across manufacturers and regions.

Core Types of Threaded Fittings

1. Thread Design Variations

Tapered Threads (Self-Sealing)

NPT (National Pipe Thread, 60° Angle):

Dominant in North America for pressure systems (water, gas, oil).

Tapered at 1:16, threads compress as they tighten, forming a mechanical seal without additional gaskets.

Ideal for high-pressure applications (e.g., industrial boilers, natural gas lines).

BSPT (British Standard Pipe Tapered, 55° Angle):

Widely used in Europe and international markets for hydraulic and fuel systems.

Features a tighter thread pitch to resist vibration-induced loosening in mobile equipment or marine environments.

Parallel Threads (Sealant-Required)

BSPP (British Standard Pipe Parallel):

Requires rubber gaskets or O-rings for sealing, common in low-pressure applications like lubrication lines or air conditioning systems.

NPSM (National Pipe Straight Mechanical):

Non-pressure threads for attaching gauges, filters, or accessories in machinery, where sealing isn’t critical.

2. Geometric Configurations

Couplings: Join two pipes of the same or different diameters (e.g., straight couplings for continuity, reducing couplings for size transitions).

Elbows: Alter flow direction (45° or 90°); long-radius elbows minimize turbulence in high-velocity pipelines.

Tees & Crosses: Create branch connections (tees for three ways, crosses for four ways), essential for distributing fluids in complex systems.

Adapters: Bridge mismatches in thread type (e.g., NPT male to BSPP female) or size (e.g., ½” to ¾”), ensuring system compatibility.

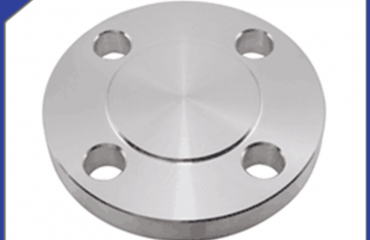

Plugs & Caps: Seal pipe ends; plugs (external threads) fit female outlets, while caps (internal threads) cover male ends during maintenance or testing.

Material Selection for Durability

Choose materials based on environmental factors and operational demands:

Stainless Steel (304/316/316L):

304: General-purpose corrosion resistance for food processing, pharmaceuticals, and mild chemical environments.

316/316L: Enhanced chloride resistance (thanks to molybdenum) for marine, saltwater, and aggressive chemical applications (316L reduces carbide precipitation in welded joints).

Carbon Steel (Galvanized/Black Iron):

High-strength and economical for industrial water, air, or steam lines; galvanized coatings protect against atmospheric corrosion.

Brass (Lead-Free Alloys):

Ideal for residential plumbing and potable water systems, offering ease of installation and resistance to low-level corrosion.

PVC/CPVC:

Lightweight, non-conductive, and chemical-resistant for drainage, irrigation, and non-pressurized water systems (CPVC rated for higher temperatures up to 200°F).

Alloy Steel (e.g., ASTM A182 F304):

Engineered for extreme conditions (high pressure/temperature) in oil refineries, power plants, and offshore platforms.

Applications Across Industries

1. Residential & Commercial Plumbing

Potable Water Systems: Lead-free brass fittings paired with PTFE tape ensure safe, leak-free connections for sinks, showers, and water heaters.

Drainage Systems: PVC fittings for lightweight, corrosion-resistant waste lines in bathrooms, kitchens, and commercial buildings.

2. Industrial Manufacturing

Pneumatic Systems: NPT fittings in compressed air lines powering factory automation, with regular torque checks to maintain vibration-resistant seals.

Chemical Processing: 316L stainless steel tees and adapters handle aggressive solvents in reactors and filtration systems, minimizing contamination risks.

3. Oil & Gas

Wellhead Equipment: Heavy-duty alloy steel fittings withstand pressures exceeding 10,000 PSI in offshore drilling, paired with metal-to-metal seals for extreme reliability.

Mobile Equipment: Quick-connect threaded adapters enable rapid assembly of pumps and hoses in remote exploration sites.

4. HVAC & Refrigeration

Chilled Water Loops: Malleable iron fittings join copper pipes in commercial AC systems, accommodating thermal expansion and contraction.

Refrigerant Lines: Flared threaded connections with O-ring seals ensure hermetic joints in low-temperature refrigeration systems.

5. Marine & Offshore

Shipboard Systems: 316 stainless steel elbows and couplings resist saltwater corrosion in desalination plants, engine cooling lines, and ballast systems.

Installation & Maintenance Best Practices

Step-by-Step Installation

Prepare Threads:

Deburr pipe ends and clean threads with a wire brush to remove debris, oils, or rust.

Inspect for damaged threads; replace fittings with bent or stripped threads to avoid leaks.

Apply Sealants Correctly:

PTFE Tape: Wrap 2–3 layers clockwise on male threads, starting 1 thread from the tip to prevent tape from protruding into the pipe bore.

Liquid Sealants: Use gas-rated compounds for natural gas lines or high-temperature sealants for steam systems; follow cure times to ensure full effectiveness.

Tighten with Care:

Hand-tighten until snug, then use a wrench for 1–2 additional turns (avoid over-tightening, which can crack fittings like PVC or deform metal threads).

For critical systems, use a torque wrench following ASME guidelines (e.g., 25–35 ft-lbs for ¾” NPT fittings in high-pressure steam).

Common Pitfalls to Avoid

Thread Mismatches: Never connect tapered (NPT/BSPT) and parallel (BSPP/NPSM) threads without a proper adapter; thread angle/size differences create incomplete seals.

Material Misuse: Don’t use brass fittings with ammonia or sulfuric acid, as they may corrode; opt for stainless steel in such environments.

Neglecting Vibration Risks: In pump or motor systems, retighten fittings annually to address loosening caused by mechanical stress.

Routine Maintenance

Leak Detection: Use soap bubbles for gas lines or visual inspection for liquid leaks; address drips or hisses immediately to prevent system damage.

Corrosion Control: In humid or coastal areas, apply anti-seize compounds to stainless steel threads to prevent galling during disassembly and use zinc-rich coatings on carbon steel fittings.

Lubrication: Regularly lubricate rarely accessed joints (e.g., valve stems) to ensure easy adjustment during maintenance.

Standards and Compliance

Adherence to international standards ensures safety and interoperability:

Thread Standards:

ASME B1.20.1 (NPT threads: dimensions, tolerances).

ISO 7-1 (BSPT threads: metric tapered threads for pressurized systems).

Material Standards:

ASTM A182 (stainless steel fittings for high-temperature service).

NSF/ANSI 61 (potable water fittings: lead content and chemical safety).

Testing Requirements: Hydrostatic pressure tests at 1.5x working pressure to validate leak resistance in critical applications.

Innovations and Future Trends

Sustainable Solutions: Growing use of recycled stainless steel (up to 90% recycled content) and eco-friendly PVC compounds to reduce environmental impact.

Smart Technology: IoT-enabled threaded fittings with embedded sensors monitor pressure, temperature, and leakage in real time, supporting predictive maintenance in industrial IoT networks.

Advanced Manufacturing: CNC machining and cold forging techniques improve thread precision and durability, while 3D printing enables custom fittings for niche applications.

Language

Language Espanol

Espanol English

English Italian

Italian عربى

عربى

Skype: chinamaker99

Skype: chinamaker99  Tel: 86-316-5120812

Tel: 86-316-5120812  Email:

Email:  Whatsapp:

Whatsapp: