In the realm of pipe systems, a flange is a crucial component that serves as a connecting element. It is a disc – shaped part with holes drilled around its circumference, designed to join pipes, valves, pumps, and other equipment in a piping network. This connection is achieved by bolting two flanges together, with a gasket placed between them to ensure a tight and leak – proof seal. Flanges play an indispensable role in various industrial, commercial, and even residential piping systems, facilitating assembly, disassembly, and maintenance of the entire setup.

The basic structure of a flange consists of a flat or slightly raised face where the gasket sits, and a series of bolt holes evenly spaced around the edge. The size of the flange, including its diameter and the number and size of the bolt holes, is standardized to ensure compatibility with corresponding pipes and components. This standardization allows for easy replacement and interchangeability, which is vital in industries where downtime must be minimized.

Flanges come in a wide range of types, each tailored to specific applications and operating conditions. Weld neck flanges are one common type, featuring a long, tapered hub that is welded to the pipe. This design provides excellent strength and is ideal for high – pressure and high – temperature systems, as the weld distributes stress evenly across the connection. Slip – on flanges, on the other hand, are slipped over the pipe and then welded in place. They are easier to install than weld neck flanges and are often used in low – to medium – pressure applications.

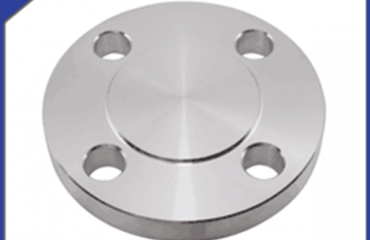

Socket – weld flanges have a socket into which the pipe is inserted, followed by welding around the outside. They are suitable for small – diameter pipes and offer good flow characteristics due to the smooth transition between the pipe and the flange. Blind flanges are solid discs used to seal the end of a pipe or close off a section of the system, commonly employed during maintenance or when a pipeline is temporarily unused.

Lap – joint flanges consist of a stub end welded to the pipe and a loose flange that fits over it. This type allows for easy alignment during installation and is often used in systems that require frequent disassembly, such as those in the food and beverage industry where regular cleaning is necessary.

The primary function of a flange in a pipe fitting is to create a secure connection. By bolting two flanges together with a gasket in between, it prevents the leakage of fluids or gases that flow through the pipes. This is critical in applications where the transported substances are hazardous, corrosive, or under high pressure, as even a small leak can lead to safety risks, environmental damage, or operational inefficiencies.

Beyond providing a leak – proof seal, flanges enable flexibility in the piping system. They allow for easy disassembly, making it possible to replace or repair components such as valves or pumps without having to cut the entire pipe. This saves time and reduces the cost of maintenance and upgrades. Additionally, flanges help in aligning pipes correctly during installation, ensuring that the flow of fluids is smooth and uninterrupted, which contributes to the overall efficiency of the system.

The materials used to make flanges vary depending on the application. Common materials include carbon steel, stainless steel, cast iron, and various alloys. Stainless steel flanges are preferred in environments where corrosion resistance is essential, such as in chemical processing plants or marine applications. Carbon steel flanges are widely used in general industrial settings due to their strength and affordability, while cast iron flanges are suitable for low – pressure, non – corrosive applications.

When selecting a flange for a specific pipe fitting, several factors need to be considered. These include the pressure and temperature of the system, the type of fluid or gas being transported, the material of the pipes, and the required level of durability. For high – pressure systems, weld neck or socket – weld flanges are typically chosen for their strength, while slip – on flanges may suffice for low – pressure setups.

Installation of flanges requires careful attention to detail. The pipes must be properly aligned to ensure that the flanges fit together evenly, as misalignment can lead to uneven pressure on the gasket and result in leaks. The gasket material must be compatible with the transported substance and the operating conditions, such as temperature and pressure. Bolts are tightened in a specific sequence to ensure uniform pressure across the flange face, which helps in creating a reliable seal.

Language

Language Espanol

Espanol English

English Italian

Italian عربى

عربى

Skype: chinamaker99

Skype: chinamaker99  Tel: 86-316-5120812

Tel: 86-316-5120812  Email:

Email:  Whatsapp:

Whatsapp: