Forged fittings are critical components in piping systems, crafted through a manufacturing process that shapes metal under high pressure and temperature. Unlike cast fittings, which are made by pouring molten metal into molds, forging enhances the metal’s structural integrity by aligning its grain structure—resulting in stronger, more durable products that excel in demanding environments. This unique production method makes them a top choice for industries where reliability and resistance to stress are non-negotiable.

One of the key advantages of forged fittings is their exceptional strength. The forging process eliminates internal defects like porosity or shrinkage, which can weaken cast alternatives. This means forged fittings can withstand higher pressure, temperature fluctuations, and mechanical stress without cracking or deforming. For example, in high-pressure oil and gas pipelines, forged fittings maintain their seal even when exposed to extreme pressure spikes, reducing the risk of leaks and operational downtime. Additionally, their resistance to corrosion is enhanced by the dense metal structure, making them suitable for use with aggressive fluids like chemicals or saltwater.

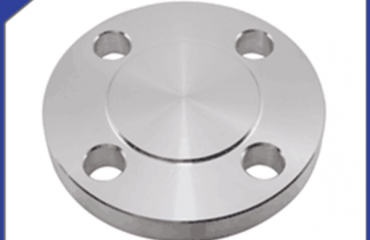

Forged fittings come in a range of types, each designed for specific piping needs. Elbows, one of the most common types, allow pipes to change direction at angles like 45° or 90°, ensuring smooth fluid flow in tight spaces. Tees are used to split or combine fluid streams, making them essential in systems where multiple pipelines intersect—such as in water distribution networks. Couplings, both full and half, connect two straight pipes, while unions provide a detachable joint for easy maintenance or repairs. Caps, on the other hand, seal the end of a pipe, preventing contamination or fluid loss in unused lines.

The applications of forged fittings span across diverse industries, driven by their durability and performance. In the petrochemical sector, they are used in refineries to handle crude oil and refined products, where high pressure and temperature are constant. The power generation industry relies on them in steam turbines and boiler systems, as they can endure the extreme heat and pressure of steam flow. Even in the construction industry, forged fittings are used in large-scale plumbing projects for commercial buildings, ensuring long-lasting connections that require minimal maintenance.

When selecting forged fittings, several factors should be considered to ensure optimal performance. Material choice is crucial—carbon steel forged fittings are ideal for general industrial use, while stainless steel options are preferred for corrosive environments. Alloy steel fittings, such as those made with chromium or molybdenum, offer enhanced strength for high-temperature applications. Additionally, ensuring the fitting’s size and pressure rating match the piping system’s requirements is essential to avoid compatibility issues.

Language

Language Espanol

Espanol English

English Italian

Italian عربى

عربى

Skype: chinamaker99

Skype: chinamaker99  Tel: 86-316-5120812

Tel: 86-316-5120812  Email:

Email:  Whatsapp:

Whatsapp: