In industrial piping systems, carbon steel flanges serve as indispensable connectors, bridging pipes, valves and equipment with reliability and efficiency. Their widespread adoption stems from a unique combination of mechanical performance, cost-effectiveness and adaptability to diverse operating conditions.

The material composition of carbon steel flanges directly shapes their functionality. Primarily crafted from iron-carbon alloys with 0.05% to 2.1% carbon content, these flanges gain strength from carbon while incorporating trace elements like manganese and silicon for enhanced properties . Common grades include ASTM A105, a mild carbon steel ideal for ambient to high-temperature pressure systems, and ASTM A350 LF2, engineered for low-temperature environments requiring notch toughness . This material versatility allows them to withstand pressures from class 150 to 2500 and temperatures across industrial extremes.

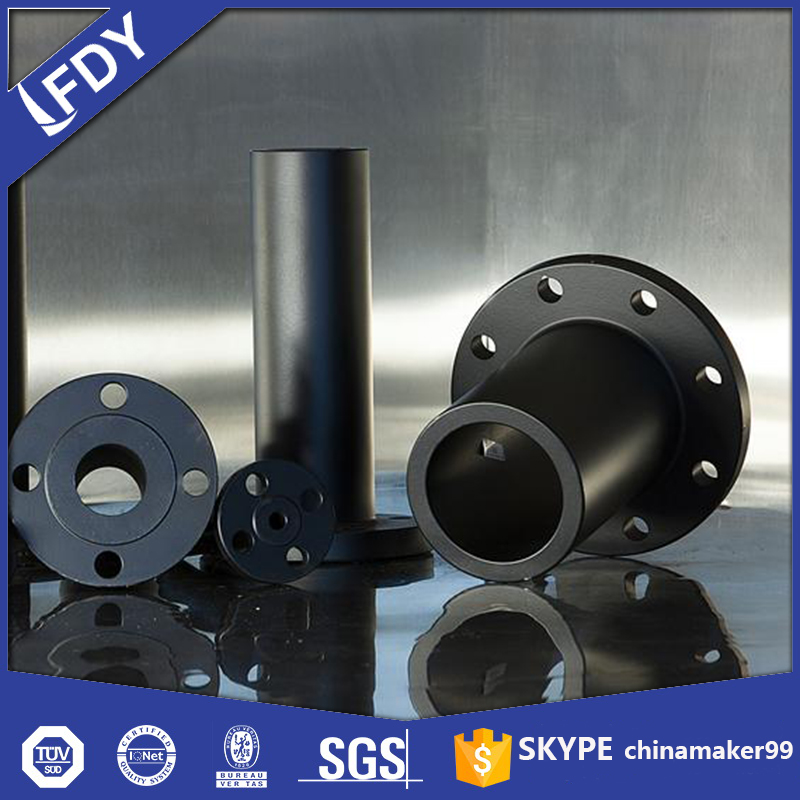

A variety of flange types cater to specific installation needs. Weld neck flanges provide robust connections for high-pressure applications, while slip-on flanges offer ease of installation for low-to-medium pressure systems . Threaded flanges eliminate welding requirements in restricted spaces, and blind flanges seal pipe ends during maintenance . Lap joint and socket weld variants further expand application possibilities, each designed to meet standards like ASME B16.5 for small diameters and ASME B16.47 for large-diameter needs.

Their industrial footprint spans nearly every sector. In oil and gas operations, they maintain leak-proof connections in drilling rigs and pipeline networks . Power plants rely on them for steam and fuel system connections, while chemical facilities value their resistance to corrosive substances . Construction and HVAC systems use them for plumbing and structural links, and even pharmaceutical and food industries utilize them for sanitary fluid transfer . Marine and automotive sectors also depend on their durability in exhaust and propulsion systems.

Adherence to global standards ensures interoperability. Specifications like DIN 2573, JIS B2220 and ISO 7005-1 govern dimensions and performance across regions . Surface finishes, from spiral serrated to smooth (Ra 3.2 micrometers), are tailored to sealing requirements, while coatings like anti-rust oil extend service life.

As a foundational industrial component, carbon steel flanges balance performance and practicality. Their material adaptability, diverse configurations and compliance with global standards make them irreplaceable in maintaining efficient, safe industrial operations worldwide.

Language

Language Espanol

Espanol English

English Italian

Italian عربى

عربى

Skype: chinamaker99

Skype: chinamaker99  Tel: 86-316-5120812

Tel: 86-316-5120812  Email:

Email:  Whatsapp:

Whatsapp: