In the complex industrial context, pipeline systems are like the blood vessels of the human body, undertaking the important mission of transporting various media. The key component that ensures these “blood vessels” can be firmly connected, sealed reliably, and withstand harsh working conditions is the flange. Among them, alloy steel flanges play an irreplaceable role in core fields with high requirements for high temperature, high pressure, and corrosion resistance due to their excellent comprehensive performance, becoming a silent and solid cornerstone in modern heavy industry and energy systems.

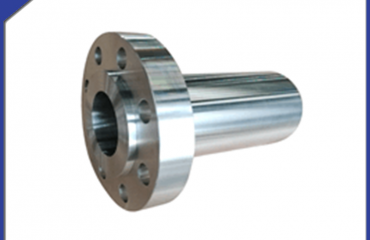

Alloy Steel Flange, as an indispensable connecting component in pipeline systems, is widely used in various industrial fields such as petroleum, chemical, power, metallurgy, etc. due to its excellent mechanical properties, corrosion resistance, and adaptability. It is made of alloy steel as raw material and precisely processed into shape, which can achieve stable connection between pipelines and between pipelines and equipment, while also considering sealing performance and structural strength, providing core guarantee for the safe operation of various industrial pipelines. It is an important basic component of the connection system in industrial production.

The essence of a flange is a connecting piece that tightly connects two pipes, valves, equipment, or other components through bolts, forming a detachable sealed whole. This disassembly is crucial as it provides great flexibility for system installation, segmented maintenance, and partial replacement. As the name suggests, alloy steel flanges are not made of ordinary carbon steel, but rather contain specific alloy elements such as chromium, molybdenum, nickel, and vanadium added during the smelting process. The addition of these elements is not simply a combination of components, but fundamentally enhances the microstructure and macroscopic properties of steel, enabling it to cope with more extreme and complex service environments.

The material properties are the core prerequisite for Alloy Steel Flange to exhibit excellent performance. Alloy steel material adds chromium, molybdenum, nickel, vanadium and other alloy elements to carbon steel, effectively improving the comprehensive performance of flanges – chromium element enhances corrosion resistance and oxidation resistance, and can adapt to humid and corrosive media environments; Molybdenum element can improve high-temperature strength and wear resistance, suitable for use under high-temperature conditions; Nickel element optimizes toughness and low-temperature performance, ensuring that it is not easily brittle in low-temperature environments. Common alloy steel flange materials include chromium molybdenum alloy steel, nickel chromium alloy steel, etc. Different materials can be adapted to different pressure, temperature, and medium conditions according to the difference in alloy ratio, meeting the diversified needs of industrial production.

The clever use of alloying elements significantly enhances the mechanical strength and toughness of the flange. In high-pressure pipeline systems, the internal medium pressure is enormous, and the connections are subjected to extremely high circumferential stress and axial tension. Ordinary materials may experience creep or plastic deformation, leading to seal failure. Alloy steel, especially chromium molybdenum steel series, has higher yield strength and tensile strength, which can maintain structural integrity for a long time and prevent deformation or cracking at the connection. At the same time, its good toughness ensures that it can resist brittle fracture even in low temperature environments and adapt to a wider temperature range.

In application scenarios, the adaptability and reliability of Alloy Steel Flange are fully demonstrated. In the field of petrochemicals, it can withstand the corrosion of crude oil, acidic and alkaline media, and high temperature and high pressure conditions, and is used for connecting refining equipment and transportation pipelines; In the power industry, pipeline systems that can adapt to equipment such as boilers and turbines can withstand long-term erosion from high-temperature steam; The metallurgical industry utilizes its high-strength characteristics to connect high-temperature medium pipelines of smelting equipment, ensuring the continuity of the production process. In addition, in fields such as municipal engineering and shipbuilding, alloy steel flanges with corresponding materials and structures can also be selected according to working conditions to achieve safe connection of pipeline systems.

Looking ahead to the future, with the development of industrial equipment towards larger scale and higher parameters, as well as the expansion of cutting-edge fields such as deep-sea energy mining and new chemical engineering, the performance requirements for pipeline connectors will become increasingly stringent, and the material research and manufacturing technology of alloy steel flanges will continue to advance.

Language

Language Espanol

Espanol English

English Italian

Italian عربى

عربى

Skype: chinamaker99

Skype: chinamaker99  Tel: 86-316-5120812

Tel: 86-316-5120812  Email:

Email:  Whatsapp:

Whatsapp: