In the vast and intricate pipeline systems of modern industry, from the steel arteries for energy transmission to the delicate veins of fine chemical processes, the safe and efficient journey of fluids at every stage relies on the impeccable reliability of each key node. Among them, butt-welded pipe fittings, with their excellent structural integrity and sealing performance, have become an indispensable connecting cornerstone in high-pressure, high-temperature, and critical process pipelines, silently carrying the heavy responsibility of maintaining the lifeline of the system.

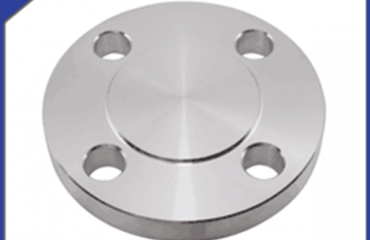

The reliability of connecting components directly impacts the stability, safety, and service life of the entire system. As a core product category, Butt Welded Fittings, with their unique structural design and excellent performance, are widely used in multiple industries. Butt welded fittings are a type of pipe accessory that connects and integrates with the end of a pipeline through welding. Their core advantage lies in the strong sealing performance and excellent mechanical properties of the overall structure formed after welding. This makes them effectively suitable for complex working conditions such as high pressure and high temperature, and they have become a key carrier for achieving functions such as medium transportation, direction change, and caliber reduction in pipeline systems.

As the name suggests, the core installation method of butt-welded pipe fittings lies in the use of welding technology to perform groove butt joint and fusion connection between the two ends of the pipe fittings and the adjacent pipeline. This connection method is far from being a simple physical contact; instead, it involves bringing the base material and the pipe fitting interface to a common molten state through high temperature, forming a continuous and homogeneous metal structure after cooling. Its fundamental advantage is established here: it provides structural strength and flow characteristics that are nearly equivalent to those of the pipeline itself. The joint formed by welding eliminates potential leakage points (such as gaskets) in flange connections, achieving a permanent, leak-free integrated connection. The inner wall is smooth and flat, providing minimal resistance to medium flow, and is less prone to scale buildup or vortex formation, making it particularly suitable for applications with stringent requirements for cleanliness and flow rate. In environments subjected to high temperature, high pressure, thermal cycling, or severe vibration, the reliability of butt-welded connections stands out.

The distinctive feature of Butt Welded Fitting lies primarily in its connection strength. Compared to pipe fittings with other connection methods, during the welding process of butt-welded pipe fittings, a continuous weld seam is formed at the connection between the pipe fitting and the pipeline. This integrated connection structure enables uniform stress distribution, avoiding the problem of localized stress concentration, thereby significantly enhancing the load-bearing capacity of the pipeline system. Whether it is for high-pressure oil and gas transmission pipelines or chemical pipelines transporting high-temperature media, butt-welded pipe fittings can ensure the stability of the pipeline system during long-term operation and reduce the occurrence of safety hazards such as leakage and rupture, thanks to their excellent connection strength.

The value of butt-welded pipe fittings is fully demonstrated in specific application scenarios. In the oil and gas industry, from subsea pipelines to high-pressure pipelines of refining and chemical plants, butt-welded pipe fittings serve as a reliable safeguard against the impact of high-pressure corrosive media. In steam pipelines and water supply systems of thermal power plants and nuclear power plants, they must withstand extreme temperature and pressure cycles. In the chemical and pharmaceutical industries, their smooth inner walls and complete sealing properties are crucial for maintaining process purity, preventing cross-contamination, and hazardous leaks. Even in high-end fields such as shipbuilding and biotechnology, butt-welded pipe fittings are preferred due to their high integrity.

In summary, as a key connecting component in pipeline systems, Butt Welded Fitting plays an irreplaceable role in multiple industrial fields due to its excellent connection strength, reliable sealing performance, and wide adaptability. With the continuous improvement of industrial production’s requirements for pipeline systems, the optimization of material selection, structural design innovation, and welding process upgrading of butt welding fittings are also continuously advancing. In the future, they will be better suited to various complex and demanding working conditions, providing a more solid guarantee for the safe and efficient operation of industrial production. In practical applications, the reasonable selection of materials, standardized welding processes, and strict quality inspection are key to fully leveraging the performance advantages of Butt Welded Fitting and are also important prerequisites for ensuring the long-term stable operation of pipeline systems.

Language

Language Espanol

Espanol English

English Italian

Italian عربى

عربى

Skype: chinamaker99

Skype: chinamaker99  Tel: 86-316-5120812

Tel: 86-316-5120812  Email:

Email:  Whatsapp:

Whatsapp: