In the dynamic landscape of industrial engineering, the significance of reliable and high – performance components cannot be overstated.

Understanding the Special Flange

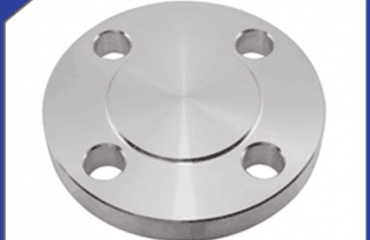

A flange, in its essence, is a crucial mechanical part used for connecting pipes, valves, pumps, and other equipment, ensuring a secure and leak – proof connection.

Design Features

Enhanced Sealing Mechanism: Our Special Flange incorporates a unique sealing design. The contact surfaces are precision – machined to an extremely high tolerance, minimizing the gaps through which fluids or gases could potentially leak. Additionally, we use specialized gasket materials that are resistant to a wide range of chemicals, temperatures, and pressures. These gaskets are designed to conform perfectly to the flange’s sealing surface, creating a tight and durable seal.

Customizable Bolt Holes: Recognizing that different applications may require different bolt – hole patterns, our Special Flange offers a high degree of customization in this regard. Whether it’s a standard pattern for easy integration with existing systems or a completely unique configuration for a specialized project, Dingyang can accommodate the needs of our customers. This flexibility not only simplifies the installation process but also ensures compatibility with a diverse range of equipment.

Integrated Stress – Relief Features: In high – stress applications, such as those involving high – pressure pipelines or machinery subject to significant vibrations, our Special Flange is designed to handle the load. It features built – in stress – relief grooves and reinforcements in critical areas. These design elements help to distribute stress evenly across the flange, reducing the risk of fatigue failure and ensuring long – term reliability.

Materials Matter

High – Grade Alloys: Dingyang‘s Special Flange is available in a variety of high – grade alloys, including stainless steels, nickel – based alloys, and carbon – manganese steels. The choice of material depends on the specific requirements of the application.

For example, in corrosive environments, such as chemical processing plants or marine applications, stainless steel alloys with high chromium and nickel content are used. These alloys offer excellent resistance to corrosion, ensuring the longevity of the flange and the connected equipment.

Advanced Composite Materials: In some cases, where weight reduction is a priority without sacrificing strength, we also utilize advanced composite materials. These composites are engineered to provide a balance of high strength and low weight, making them ideal for applications in the aerospace and automotive industries. The use of composite materials in our Special Flange not only improves performance but also contributes to overall system efficiency.

Applications Across Industries

Oil and Gas: In the oil and gas industry, where pipelines transport highly pressurized and often corrosive substances over long distances, reliability is of utmost importance. Dingyang‘s Special Flange is used in pipeline connections, wellheads, and refinery equipment. Its superior sealing capabilities and resistance to harsh environments make it a preferred choice for ensuring the safe and efficient operation of oil and gas facilities.

Power Generation: Whether it’s a thermal power plant, a hydroelectric facility, or a nuclear power station, power generation requires components that can withstand extreme temperatures and pressures. Our Special Flange is used in steam pipelines, cooling water systems, and turbine connections. The ability to handle high – temperature steam and corrosive cooling water, combined with its high – strength construction, makes it an essential part of power generation infrastructure.

Chemical Processing: Chemical plants deal with a wide variety of aggressive chemicals. Our Special Flange, with its chemical – resistant materials and tight – sealing design, is used in the transfer of chemicals, in reactors, and in storage tank connections. It helps to prevent leaks of hazardous substances, ensuring the safety of plant personnel and the environment.

Quality Control: Quality control is an integral part of our manufacturing process. Each Special Flange undergoes a series of rigorous inspections, including dimensional checks, material testing, and pressure testing. We use advanced non – destructive testing methods, such as ultrasonic testing and magnetic particle inspection, to detect any potential defects. Only flanges that meet our strict quality standards are released for delivery.

Whether you are in the oil and gas, power generation, or chemical processing sector, Dingyang‘s Special Flange is the connection solution you can trust.

Language

Language Espanol

Espanol English

English Italian

Italian عربى

عربى

Skype: chinamaker99

Skype: chinamaker99  Tel: 86-316-5120812

Tel: 86-316-5120812  Email:

Email:  Whatsapp:

Whatsapp: