Malleable iron fittings play a crucial role in various industries, especially in piping systems where they are used to connect, divert, or terminate pipes. These fittings are made from malleable iron, a material with unique properties that make it highly suitable for a wide range of applications.

Material Composition and Manufacturing Process

Malleable iron is produced by first casting white cast iron, which has a high carbon content. The white cast iron is then subjected to a special heat treatment process called annealing. During annealing, the white cast iron is heated to a temperature above 900 °C and held at that temperature for an extended period, followed by slow cooling. This process changes the microstructure of the iron. The carbon in the white cast iron, which is initially in the form of cementite (a hard and brittle compound), decomposes into graphite nodules with a more irregular and rounded shape. This transformation results in a material that combines high tensile strength with flexibility, unlike regular cast iron which is more brittle.

Types of Malleable Iron Fittings

There is a diverse range of malleable iron fittings available, each designed to serve a specific function in piping systems:

Elbows: These are used to change the direction of the pipeline. 90 – degree elbows are common for making sharp turns, while 45 – degree elbows are used for more gentle bends. Street elbows are a type where one end has a male thread and the other has a female thread, allowing for easy connection to pipes of different threading types.

Tees: Tees are used to create a branch in the pipeline. Equal tees have three openings of the same size, while reducing tees are designed to connect pipes of different diameters at the branch point. They are essential for distributing fluids or gases to multiple destinations.

Couplings: Couplings are used to join two straight pipe sections together. They ensure a secure and leak – proof connection. Some couplings are designed for use with pipes of the same diameter (equal couplings), while others can connect pipes of different sizes (reducing couplings).

Unions: Unions are a type of fitting that allows for easy disconnection and reconnection of pipes. They consist of three parts: two end pieces that thread onto the pipes and a middle nut. This design is useful in situations where pipes need to be serviced or replaced without having to cut or weld the entire system.

Reducers: Reducers are used to connect pipes of different diameters. They smoothly transition from a larger – diameter pipe to a smaller – diameter one, ensuring that the flow of the fluid or gas is not disrupted.

Caps and Plugs: Caps are used to seal the end of a pipe, while plugs are inserted into a threaded opening to block the flow. They are often used when a section of the pipeline needs to be temporarily or permanently closed off.

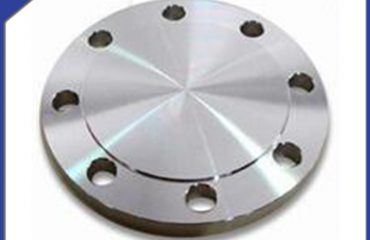

Floor Flanges: These are used to anchor pipes or other equipment to the floor. They provide a stable base and are popular in applications where equipment needs to be firmly secured.

Applications Across Industries

Plumbing Systems: In residential, commercial, and industrial plumbing, malleable iron fittings are widely used. They are used to transport water, whether it’s for potable water supply, drainage systems, or in heating and cooling systems. Galvanized malleable iron fittings are particularly popular in water supply systems as the zinc coating provides excellent corrosion resistance, protecting the fittings from the effects of water and extending their lifespan.

Gas and Oil Pipelines: Malleable iron fittings, especially black malleable iron fittings, are commonly used in gas and oil pipelines. Their high strength and durability allow them to withstand the high pressures and harsh conditions associated with the transportation of these fluids. They are used to create leak – proof connections and ensure the safe and efficient flow of gas and oil.

Irrigation Systems: In agricultural and landscape irrigation, malleable iron fittings are used to connect pipes that carry water for irrigation purposes. Their ability to handle different water pressures and resist corrosion from water and soil – related elements makes them a reliable choice.

Industrial Machinery and Equipment: Malleable iron fittings are used in the construction of industrial machinery and equipment that involves fluid or gas transfer. They can be found in cooling, lubrication, and pneumatic systems, where their strength and flexibility are essential for withstanding the mechanical stresses and vibrations associated with industrial operations.

Advantages of Malleable Iron Fittings

Strength and Durability: Malleable iron fittings are known for their high tensile strength. They can withstand significant pressure, temperature changes, and mechanical stress without deforming or breaking. This makes them suitable for use in demanding applications where reliability is crucial.

Corrosion Resistance: Galvanized malleable iron fittings offer excellent protection against corrosion. The zinc coating acts as a sacrificial layer, corroding in place of the iron base material. Even if the coating is scratched or damaged in some areas, the zinc will continue to protect the iron through a process called cathodic protection.

Versatility: With the wide variety of fitting types available, malleable iron fittings can be used in almost any piping system configuration. They can handle different types of fluids, including water, gas, oil, and various chemicals, making them suitable for a diverse range of industries.

Ease of Installation: Most malleable iron fittings have threaded connections, which are relatively easy to install. This reduces the need for specialized welding or soldering equipment, making installation quicker and more cost – effective, especially in large – scale projects. The threads provide a secure and leak – proof connection when properly tightened.

Cost – Effectiveness: Compared to fittings made from more exotic materials such as stainless steel or brass, malleable iron fittings are relatively affordable. Their combination of cost – effectiveness, durability, and versatility makes them an attractive option for both small – scale and large – scale projects.

Language

Language Espanol

Espanol English

English Italian

Italian عربى

عربى

Skype: chinamaker99

Skype: chinamaker99  Tel: 86-316-5120812

Tel: 86-316-5120812  Email:

Email:  Whatsapp:

Whatsapp: