Forging temperature range refers to the temperature interval between the initial forging temperature and the final forging temperature.

In order to improve the plasticity and reduce the deformation resistance, we hope to increase the heating temperature of metal as much as possible; However, in order to ensure product quality and avoid defects in heating, the heating temperature is too high and bad. In order to reduce the number of fires, save energy and improve labor productivity, not only the heating temperature is expected to be high, but also the temperature at the end of forging is expected to be lower; However, in order to avoid serious work hardening and lead to forging cracks, stop forging temperature should not be too low. It can be seen that these factors are contradictory and mutually restricted, so the determination of forging temperature range must be considered comprehensively.

The basic principles for determining forging temperature range are as follows:

1. Ensure that the metal has better plasticity and lower deformation resistance in the forging temperature range.

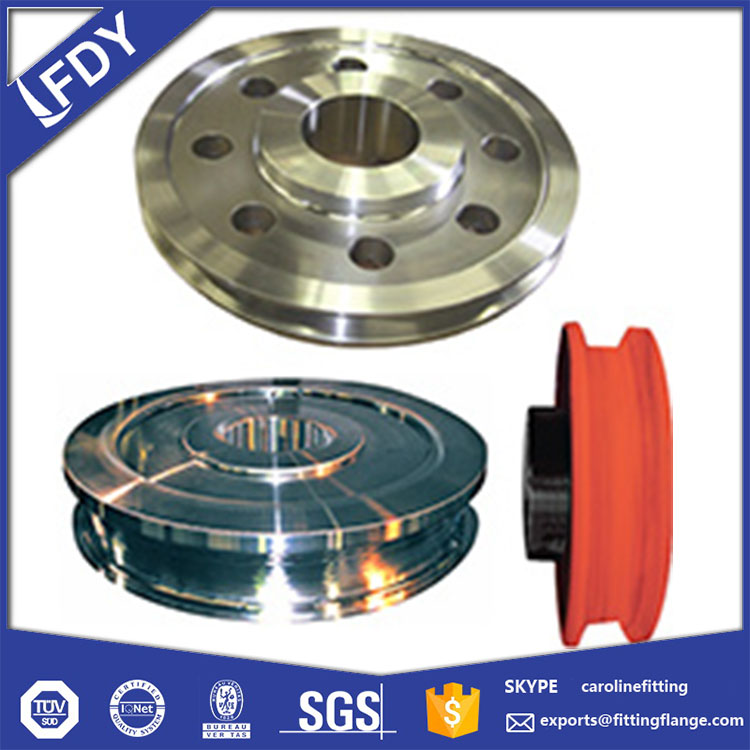

2. Ensure the forged wheel with good quality (internal structure and mechanical properties).

3. Expand the forging temperature range as much as possible, so as to reduce the fire, save energy and improve the forging productivity.

In consideration of the above principles, it is necessary to establish the idea of quality first. First of all, it is necessary to ensure that the billet heating is excellent, so as to ensure the forging of high quality wheel and good plasticity. At the same time, it is necessary to reduce the heating times, improve the labor productivity and reduce the heat loss.

Language

Language Espanol

Espanol English

English Italian

Italian عربى

عربى

Skype: chinamaker99

Skype: chinamaker99  Tel: 86-316-5120812

Tel: 86-316-5120812  Email:

Email:  Whatsapp:

Whatsapp: